ULTRASONIC TESTING (UT)

02 Jul 2022 Download PDF

Ultrasonic testing comprises a range of non-destructive testing (NDT) techniques that send ultrasonic waves through an object or material. These high-frequency sound waves are transmitted into materials to characterize the material or for flaw detecting. Most UT inspection applications use short pulse waves with frequencies ranging from 0.1-15 MHz, although frequencies up to 50 MHz can be used. One common application for this test method is ultrasonic thickness measurement, which is used to ascertain the thickness of an object such as when assessing pipework corrosion.

How does it Work?

Ultrasonic inspection uses a piezoelectric transducer connected to a flaw detector, which in its most basic form is a pulse-receiver and oscilloscope display. The transducer is passed over the object being inspected, which is typically coupled to the test object with gel, oil, or water. This couplant is required to efficiently transmit the sound energy from the transducer into the part, however, This couplant is not required when performing tests with non-contact techniques such as electromagnetic acoustic transducer (EMAT) or laser excitation.

Pulse-echo and Through-transmission

Ultrasonic testing can be performed using two basic methods – pulse-echo and through-transmission.

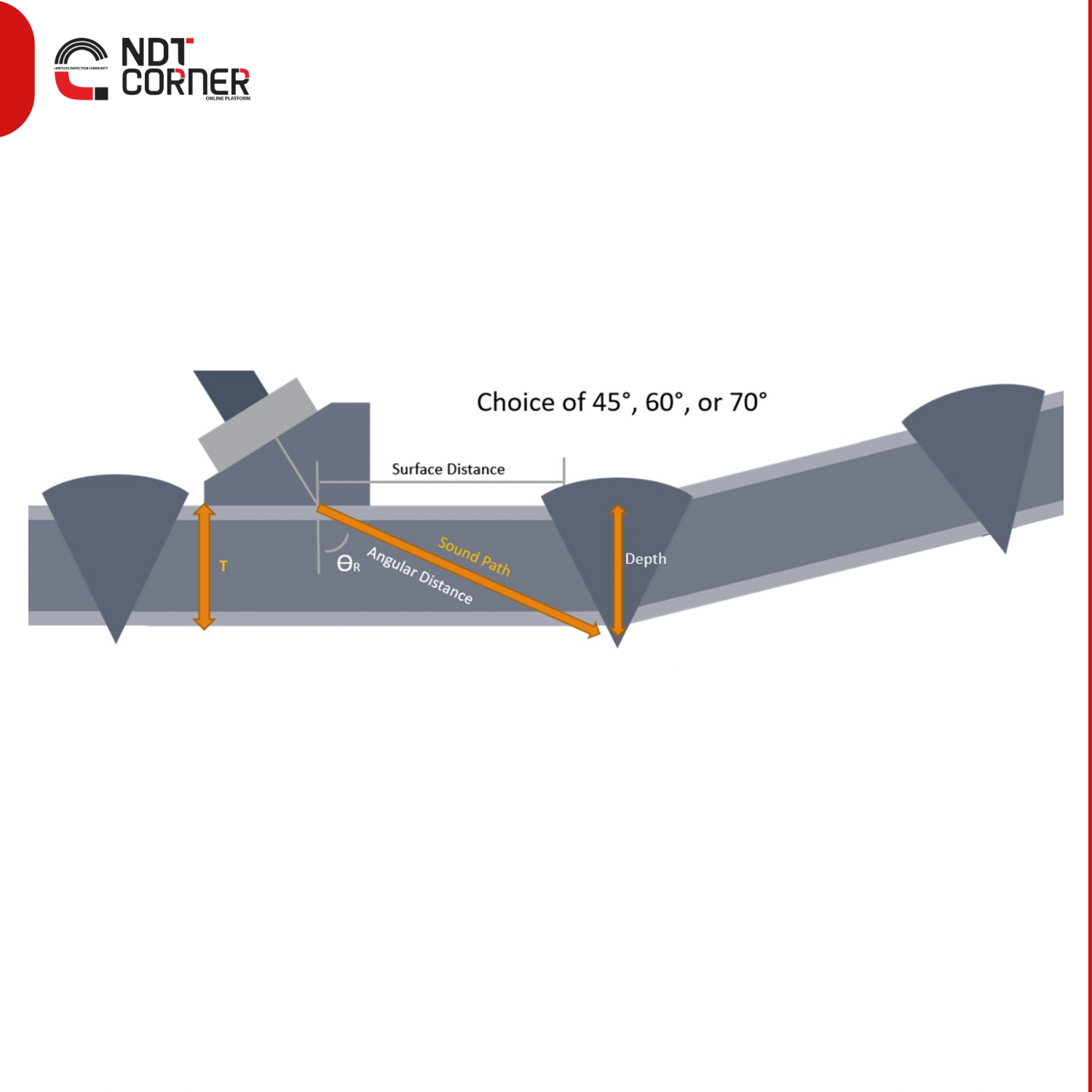

With pulse-echo testing, the same transducer emits and receives the sound wave energy. This method uses echo signals at an interface, such as the back of the object or an imperfection, to reflect the waves back to the probe. Results are shown as a line plot, with an amplitude on the y-axis representing the reflection’s intensity and distance or time on the x-axis, showing the depth of the signal through the material.

Through-transmission testing uses an emitter to send the ultrasound waves from one surface and a separate receiver to receive the sound energy that has reached the opposite side of the object. Imperfections in the material reduce the amount of sound that is received, allowing the location of flaws to be detected.

Contact and Immersion Testing

Ultrasonic testing can also be split into two main types: contact or immersion testing.

Contact ultrasonic testing is typically used for on-site inspection accessibility or portability. Contact ultrasonic inspection can be performed where only one side of a test specimen is reachable, or where the parts to be tested are large, irregular in shape, or difficult to transport.

Immersion ultrasonic testing is a laboratory-based or factory-based non-destructive test that is best suited to curved components, complex geometries, and ultrasonic technique development. In this method, the component or material is submerged in water, which acts as a coupling in place of the gels used for contact ultrasound. Immersion UT generally uses the pulse-echo method, and robotic probe trajectories can be used to inspect complex surfaces which would be hard to cover with contact probes. Immersion UT can be used for a wide range of wall thickness and material types, making it a suitable testing method for a variety of applications and industries.

Why is it Used?

As a non-destructive testing method, ultrasonic testing is ideal for detecting flaws and defects without damaging the object or material being tested. Periodic ultrasonic inspections can also be used to check for corrosion or for growth of known flaws, and thus potentially prevent a failure of a part, component, or entire asset. It is used in a wide range of industries including aerospace, automotive, construction, medical, metallurgy, and manufacturing.

What Materials Can Be Tested?

Ultrasonic testing is used in a wide range of industries due to its suitability for many different materials. UT is ideally used for the inspection of dense, crystalline structures such as metals. Ceramics, plastics, composites, and concrete can also be successfully inspected but with reduced resolution, since the attenuation in these materials is higher.

Ultrasonic technology has been successfully employed in the medical sector for many decades and is increasingly the preferred option for both routine diagnostic imaging and medical research because of the absence of ionising radiation.

Advantages

The advantages of ultrasonic testing include:

- High penetration power, allowing for flaw detection deep within a part

- High sensitivity, allowing for the detection of very small flaws

- Can be used to test when only one side of an object is accessible

- Greater accuracy, when compared to other non-destructive testing methods, for determining the depth of internal flaws and the thickness of parts with parallel surfaces

- Able to estimate size, shape, orientation, and nature of defects

- Able to estimate alloy structures of components with differing acoustic properties

- Non-hazardous to nearby personnel, equipment, or materials

- Highly automated and portable operations are possible

- Immediate results can be obtained, allowing for immediate decisions to be made

Limitations

There are, however, a few limitations to ultrasonic testing, as follows:

- Requires experienced technicians for inspection and for data interpretation

- False-positive results, also known as spurious signals, may result from tolerable anomalies as well as the component geometry itself

- Objects that are rough, irregularly shaped, very small or thin, or not homogeneous are difficult to inspect

- Loose scale or paint will need to be removed before testing can commence, although clean, properly bonded paint can be left in place

- Couplants required for tests that use conventional UT

- UT may have reduced sensitivity for volumetric flaws, particularly metal inclusions, than radiographic testing

Applications

Ultrasonic testing has a variety of applications across the industry, including testing the integrity of a material or component. This can include testing of welds to determine if there are any discontinuities present. This testing can be performed on both ferrous and non-ferrous materials as well as for thicker sections and those that are reachable from one side only. UT is also capable of detecting finer defects and planar flaws which may not be assessed as readily with radiographic testing.

Applications for UT include those within the aerospace, automotive, construction, rail, medical, and oil and gas industries.